Why Marine Diesel Generator Failures Are Often Design Problems

Introduction: When Equipment Gets Blamed for System Decisions

When a marine diesel generator fails offshore, the first reaction is often: “the hardware is unreliable.” It sounds clean. It is also often wrong. In a diesel generator marine project, the engine and alternator are the last link in a chain of design choices. Heat paths, engine room ventilation, load behavior, cable routing, control interaction, and fuel handling decide whether a genset runs with margin or lives on the edge.

This article avoids repair talk and brand debates. It focuses on what EPC teams and operators care about: why common marine diesel generator failures lare framed as hardware issues, but actually begin with design choices that quietly drive downtime cost.

The Pattern Behind Marine Diesel Generator Failures

Failures rarely arrive as one dramatic event. They show up as repeats: a trip, a hot alarm, a “watch it” note, then another port delay. Repeated instability often signals a system designed to pass acceptance, not a system built for real duty cycles.

Failures Rarely Start With the Engine Itself

The engine is visible, so it gets blamed. Yet many marine these failures begin outside the engine block. Ventilation constraints, heat buildup in a tight enclosure, and electrical integration details that look minor on paper can push the system into unstable behavior. Fuel quality variability can also act like a slow leak in reliability when storage and routing were planned for ideal conditions.

Treat these as design inputs, and you reduce the odds of downtime instead of chasing symptoms.

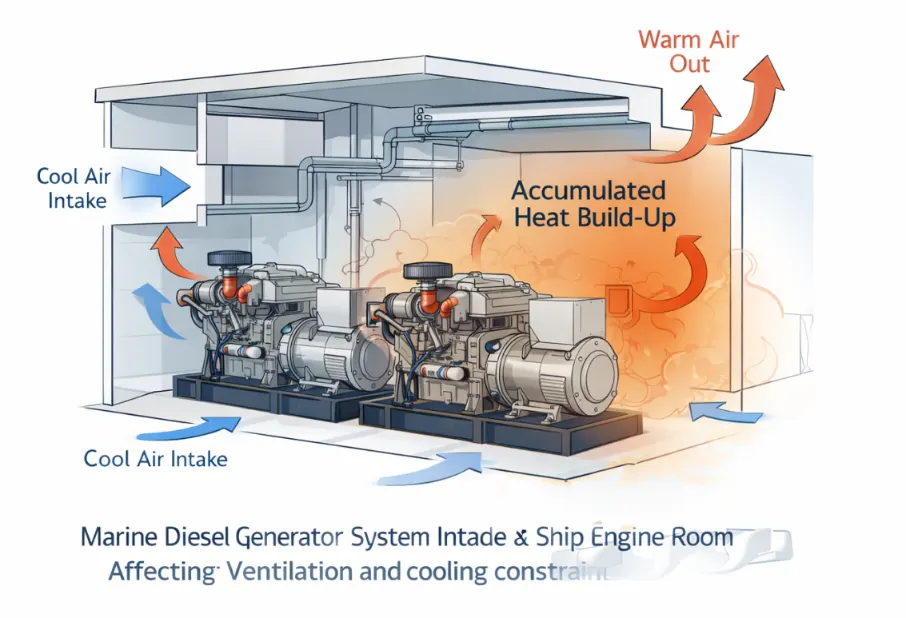

Design Problem One: Heat, Airflow, and Engine Room Reality

Heat management is not a comfort topic. It is a reliability budget. In a confined engine room, the system either moves heat out or stores it until something complains.

Why Engine Room Ventilation Matters More Than Nameplate Power

A genset can be sized correctly and still be wrong for the space. If engine room ventilation limits fresh air intake or restricts hot air discharge, temperature rises become normal. Then every hard run feels like a stress test.

This is why nameplate power can mislead in marine power systems. Real output is what the generator sets can deliver without sliding into heat buildup that triggers alarms, derates, or protection trips.

How Small Thermal Margins Lead to Repeated Downtime

Thermal margin is not “it overheated once.” It is “it runs slightly hot every day.” Daily heat reduces electronics tolerance, ages wiring, and tightens the system’s error window. Crews often respond by avoiding peak loads “just in case.” That habit costs money even when the genset never trips.

Design Problem Two: Load Profile Assumptions That Do Not Match Reality

Many projects treat load profile as a spreadsheet. Real vessels treat load as behavior. It changes with weather, routing, onboard routines, and the operating cycles.

Continuous Load vs Real Vessel Load Behavior

A marine diesel generator often runs in continuous load duty, closer to prime power than standby power. That matters because continuous operation exposes weak assumptions. Hotel load, pumps, compressors, and auxiliaries do not behave like a steady lab load. They stack, drop, and spike.

If the design assumes “average load,” but the vessel lives in “long steady demand plus short bursts,” the genset spends its life reacting.

Step Load and Load Priority Often Get Simplified Too Early

Step load events are normal: motor starts, large pumps, sudden auxiliary demand. If step load behavior is treated as a footnote, you may see repeated frequency dips, voltage swings, or nuisance trips that look like the diesel generator marine problems.

Load priority is the other hidden piece. If the wrong loads stay online during a disturbance, a small event can turn into cascading instability.

Design Problem Three: Electrical Integration Is Treated as Secondary

Electrical integration is quiet work. It is also where “it should work” turns into “it works until it doesn’t.”

Control Systems, AVR, and Real-World Stability

Controls and AVR behavior can look fine during checks. Trouble appears under real switching and real step load conditions. If sensing, response timing, and control interaction do not match vessel behavior, the genset can bounce between stable and unstable states. That gets blamed on the diesel generator, even when the system design invited it.

Grounding and Power Quality as Failure Multipliers

Power quality issues often do not cause instant shutdown. They create stress: extra heat in cables, noise in signals, and control drift. Stress becomes fault events later, offshore, where recovery window is limited.

Design Problem Four: Fuel Systems Are Designed for Availability, Not Reality

Fuel is treated like a supply issue. In marine applications, fuel is also a reliability variable.

Fuel Quality Variability and Storage Effects

Fuel quality variability can separate stable operation from rough starts and alarm chains. Storage conditions add risk too. Water and contamination do not always stop diesel generators at once. They often create gradual instability that shows up at the worst time.

Filtration and Fuel Routing as Design Decisions

Fuel system design is not a maintenance topic. It is a tolerance topic. Routing, separation stages, and how the system handles contamination determine how often fuel conditions become operational problems.

Design Problem Five: Service Access and Recovery Windows

A design can be technically correct and still be operationally wrong if critical points are hard to reach.

Access Limits Increase Downtime Probability

Service access affects how fast small issues get noticed. If access is tight, inspections happen less. Adjustments take longer. Some checks get skipped during busy schedules. That is not a crew problem. It is a design problem.

Why “Can Be Fixed Later” Is a Risky Assumption at Sea

At sea, there is no easy swap and no workshop around the corner. When failure happens, the vessel may run in degraded mode until port. That is why small issues can become expensive.

Reframing Marine Diesel Generator Failures

The decision question is not “which diesel generator is best.” It is “which design choices reduce failure probability.”

From Hardware Quality to System Failure Tolerance

Hardware quality matters, but failure tolerance is the anchor. Thermal margin, step load reserve, and stable electrical integration drive system-level reliability.

A quick way to keep the conversation design-first:

|

Design Area |

Typical “Equipment” Symptom |

Design Question That Matters |

|

Heat / Airflow |

Hot alarms, derate |

Where does hot air go, and how does fresh air enter? |

|

Load Profile |

Nuisance trips |

What is the real continuous load and worst step load? |

|

Electrical Integration |

Voltage swings |

How do controls behave during switching and load steps? |

|

Fuel System Design |

Rough starts, alarms |

How does the system tolerate fuel quality variability? |

|

Service Access |

Long outages |

How fast can you reach critical points offshore? |

What EPC Teams Should Ask Before Finalizing Design

Before design is locked, EPC teams can ask a few blunt questions:

- What is the real load profile, not the averaged one?

- What happens during the worst step load event?

- What are the heat paths, and where can heat buildup occur?

- Which loads get priority when stability drops?

- What is the recovery window offshore, and what access limits slow it down?

These questions sound basic. They decide whether a genset becomes a tool or a recurring problem.

Conclusion: Design Choices Decide Failure Long Before Startup

Many marine diesel generator failures are predictable outcomes of ventilation constraints, high continuous load, simplified load priority, fragile electrical integration, and fuel system design that assumes ideal conditions. Treat these as design inputs, and downtime becomes less frequent and less costly. When they are ignored, system decisions get misread as hardware failures.

Uleengen (Shandong Uleen Generator Co., Ltd.)

Uleengen (Shandong Uleen Generator Co., Ltd.) supplies diesel generators, generator sets, and marine-oriented genset solutions for projects that value stable power in real operating conditions. The focus stays practical: match duty cycle, installation limits, and control needs instead of selling a one-size story. For marine applications, that means power continuity, integration readiness, and project support that fits EPC workflows. When the goal is fewer repeat outages driven by heat buildup, load profile mismatch, electrical integration gaps, or fuel quality variability, Uleengen supports generator sets packages built around the way vessels actually run.

FAQ

Q1: Why are marine diesel generator failures so often blamed on the machine itself?

A: Because the engine is visible. Design problems like engine room ventilation limits, load profile mismatch, and electrical integration issues are harder to see, but they often start the chain.

Q2: What design issue causes the most repeat downtime offshore?

A: Heat and airflow. Small ventilation constraints can erase thermal margin during continuous load duty.

Q3: How does load profile affect diesel generator marine reliability?

A: If the design assumes steady demand but the vessel sees frequent step load events, the genset keeps reacting. That reaction is where instability starts.

Q4: Can power quality really cause failures in marine power systems?

A: Yes. Poor power quality adds stress over time, and stress often turns into faults offshore where recovery window is limited.

Q5: What should EPC teams check early to cut marine diesel generator failures?

A: Real load behavior, heat paths, service access, electrical integration behavior, and fuel system tolerance for fuel quality variability.