How Does a Generator Natural Gas System Work in Real Power Projects?

When you hear “ natural gas generator,” it can sound simple: gas goes in, electricity comes out. Real projects are messier than that. Fuel pressure changes, loads jump, and someone always plugs in a motor at the worst moment. So the real question becomes: how does a natural gas generator work when it is tied into a site with real crews, real equipment, and real downtime costs?

This article breaks down how a generator natural gas system works from fuel supply to stable power output, then shows what changes once the set is running a jobsite, plant, or facility. You will also see where gas makes sense, where diesel still wins, and what to watch before you commit to a fuel path.

Why Generators Using Natural Gas Are Common in Modern Power Projects

In many regions, natural gas is simply easier to keep flowing than liquid fuel. You do not have to schedule deliveries, manage tanks, or worry about theft as much. That is why generator natural gas setups show up in industrial parks, commercial facilities, and infrastructure sites that plan for long-hour operation.

The other reason is predictability. In real power projects, you care about stable output, manageable maintenance, and a fuel supply that does not become a daily headache. A generator tied to a steady gas source can run like part of the utility plan rather than a temporary patch.

What Is a Generator Natural Gas System Made Of?

A generator natural gas system is not just an engine and an alternator. It is a small power plant with fuel handling, combustion control, electrical conversion, and protection logic. Once you see the pieces, it becomes easier to answer the question how does a natural gas generator work in a practical, site-ready way.

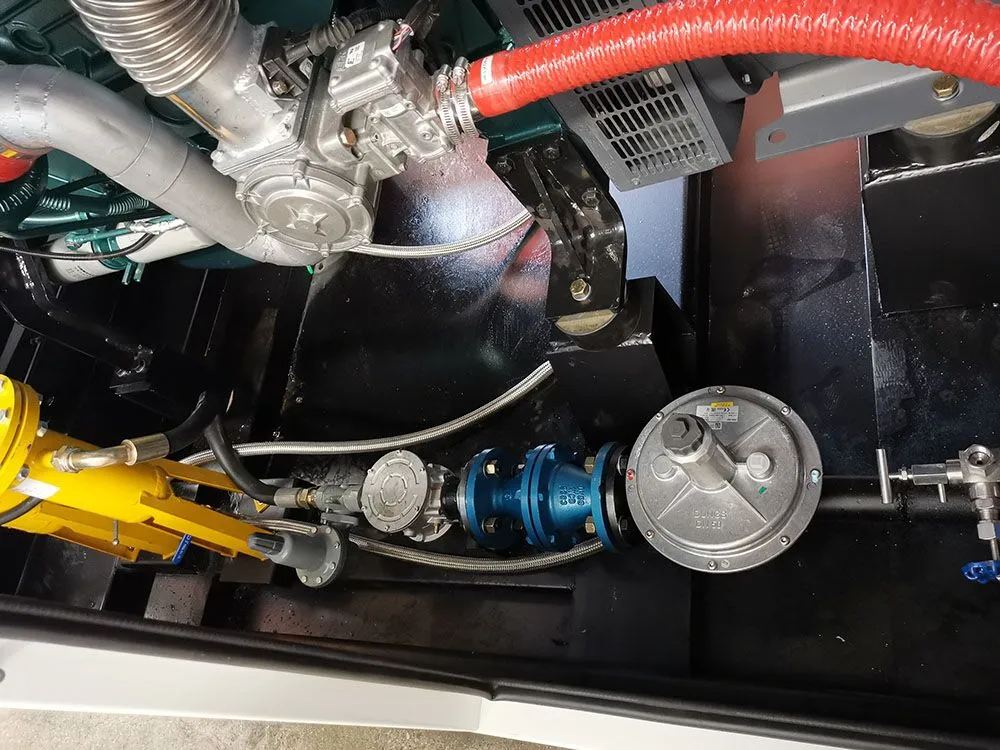

Natural Gas Supply and Pressure Regulation

Natural gas usually arrives from a pipeline or a regulated site supply. Before it reaches the engine, it passes through components that control pressure and flow. This matters more than most people expect. If gas pressure drops under load, the engine can stumble, power quality can drift, and alarms can start stacking up.

In real power projects, fuel supply is part of the broader power systems plan. If the gas line is shared with other users on site, pressure stability becomes a design topic, not an afterthought.

Gas Engine and Combustion Process

The core of many gaseous generators is a spark-ignited gas engine. Natural gas mixes with air, enters the cylinders, and ignites. That controlled combustion pushes pistons and creates mechanical rotation.

This is one reason generators that run on natural gas can feel smooth under steady loads. Combustion is consistent when the fuel supply is consistent. But it also means fuel quality and pressure control matter. If the fuel feed is unstable, the engine cannot “muscle through” the way a well-fueled diesel electric generator often can.

Alternator and Power Generation

The alternator is where mechanical rotation becomes electrical output. The engine spins the rotor, magnetic fields move, and the stator produces electricity. That electricity then feeds your electric equipment, from motors and pumps to control cabinets and lighting.

In real projects, the alternator is also where you pay for bad load behavior. Large motor starts, poor power factor, or sudden load rejection can stress the generating set. The alternator does not care that your schedule is tight.

Control Panel and Monitoring System

The controller is the brain. It manages start and stop sequences, monitors temperature and pressure, and keeps frequency and voltage within safe limits. It also trips the unit when something drifts into a dangerous zone.

This is where project-grade systems differ from casual “backup only” thinking. In stable power projects, control logic is part of the reliability story. It is also part of the maintenance story, because good monitoring catches small problems before they become a site shutdown.

Step-By-Step: How a Generator Natural Gas System Produces Electricity

There is a simple way to explain how does a natural gas generator work without turning it into a textbook. Think of it as a chain. If any link is weak, the whole system suffers.

-

Natural gas enters the system and passes through regulation components that steady pressure and flow.

-

The fuel mixes with air in the intake path and reaches the combustion chamber.

-

Spark ignition starts controlled combustion, creating mechanical power.

-

The engine shaft rotates and drives the alternator.

-

The alternator converts mechanical energy into electrical energy.

-

The controller stabilizes output and protects the set when load or fuel conditions change.

That is the working principle of a gas electric generator in plain terms. The rest of the article is about what happens when you apply that chain to real load patterns.

How Generator Natural Gas Systems Behave Under Load

In a brochure, loads look neat. In the field, loads are chaotic. Your pumps start late, your compressors short-cycle, and someone adds equipment mid-shift. This section matters because most “it worked in the shop” failures happen here, not in the fuel chemistry.

Load Changes and Response Time

When load rises, the engine needs more fuel and air quickly. The control system adjusts, the fuel system reacts, and the engine tries to hold speed. If that response is slow, frequency dips. If it overshoots, you can get instability.

This is why you should think about your load profile, not just the kW total. A site full of motor starts and variable loads may need a different configuration than a steady base load. Your electric equipment decides the stress level more than the nameplate rating.

Continuous and Prime Power Operation

Generator natural gas systems are often selected for prime or long-hour duty because fuel logistics can be simpler. Still, continuous operation is not “set and forget.” You need airflow, maintenance access, and a realistic plan for service intervals.

The best long-hour results usually come from a balanced load strategy, not from running on the edge. In real power projects, you want margin. Not because you love overspending, but because you hate emergency service calls more.

Generator Natural Gas vs Diesel in Real Power Projects

If you are choosing between gas and diesel, keep it practical. Diesel often wins on raw tolerance. It can handle rugged logistics, sudden load steps, and remote conditions when gas supply is uncertain. A diesel electric generator is still the default answer in many off-grid or temporary sites for a reason.

Gas can win when supply is stable and runtime is long. It can reduce fuel handling work and simplify site routines. In mixed fleets, it is common to see generator natural gas systems assigned to stable, long-hour duties, while diesel covers mobile, remote, or high-variability work. Call it the “right tool” approach, not a brand war.

Typical Applications of Generator Natural Gas Systems

This is where “real power projects” stops being a phrase and becomes a checklist. Generator natural gas setups show up most often in:

-

Industrial facilities with steady loads, where an industrial generator can run for long periods with predictable demand

-

Commercial buildings that want standby support with cleaner, simpler fuel supply

-

Infrastructure and utility-adjacent sites where fuel delivery risk is a major concern

-

Facilities that treat backup power as part of business continuity, not just emergency lighting

You may still use a standby generator approach with gas. It is just a different standby plan. Less fuel storage, more reliance on the gas network.

Practical Limits and Considerations

Gas is not magic. If the site has unstable gas pressure, poor regulation, or uncertain supply, your risk rises. Also, if the project is truly remote, diesel logistics might still be easier than building gas supply reliability.

Another reality: site conditions still matter. Heat, ventilation, dust, and maintenance habits affect reliability. A generator natural gas system can be very stable, but only when the system around it is treated seriously.

Where Uleengen Fits Into Real Power Projects

When you move from theory to procurement, you need equipment that matches how your project runs. In many cases, the easiest user path is to start from the category level and work down. That is where a generator natural gas system (internal link anchor) overview helps you compare configurations and project fit.

For engine-based solutions, you may also be looking at specific platforms. In project-based applications, Uleengen provides gas generator solutions based on Cummins engines (internal link anchor) that are built for steady operation and practical site demands.

And if your project planning includes multiple fuel types, enclosures, or generator set families, it helps to view a full range of power generation equipment (internal link anchor) so your selection stays consistent across sites and expansion phases.

FAQ

Q1: How does a natural gas generator work in simple terms?

A: Fuel is regulated, mixed with air, ignited in a gas engine to create mechanical power, then an alternator converts that rotation into electricity while controls keep voltage and frequency stable.

Q2: Is generator natural gas better than diesel for every jobsite?

A: No. Gas is strong when supply is stable and runtime is long. Diesel often wins when fuel logistics are simpler, loads are messy, or the site is remote.

Q3: What makes a generator natural gas system unstable on site?

A: The common causes are fuel pressure swings, poor regulation, sudden load steps, weak ventilation, and skipped maintenance.

Q4: Can a natural gas generator run for long hours in real projects?

A: Yes, if the fuel supply is reliable and you follow a service plan. Long-hour operation is usually more about discipline than marketing claims.

Q5: What should you check before choosing a gas-based generator setup?

A: Confirm fuel supply stability, expected load behavior, maintenance access, ventilation, and whether your project needs prime, standby, or mixed-duty operation.