Marine Generators for Amazon River Fleets Humidity & Fuel Solutions

When you operate within the Amazon Basin, the rainforest does not care about your shipping schedule. Navigating thousands of kilometers between Belém, Manaus, and Iquitos places a unique strain on your vessel that standard coastal equipment simply cannot handle. In this environment, your ship diesel generator is not just an auxiliary machine; it is the lifeline that keeps your navigation, cooling, and safety systems alive. Amazon River logistics demand a level of resilience that balances high output with the brutal reality of the tropics.

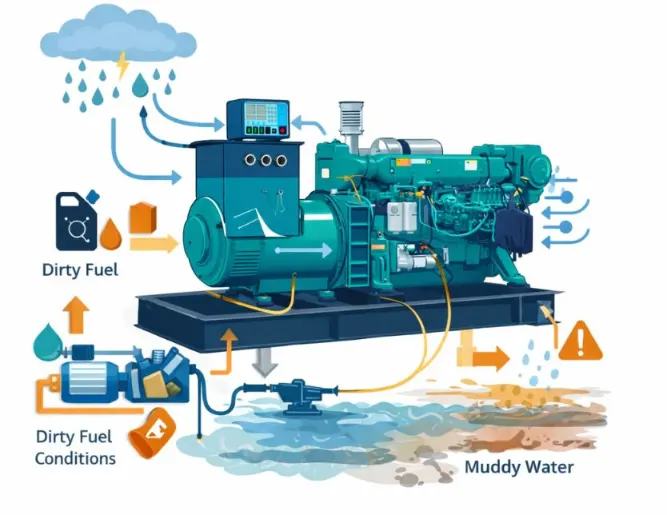

The Harsh Reality: Why Standard Generator Systems Fail in the Amazon

Most diesel generators are designed for clean environments with stable temperatures. The Amazon offers the exact opposite. Between 90% humidity and the constant threat of silt-heavy water, a standard marine diesel generator often struggles within months. If you treat your power needs like a land-based project, you risk massive operational failure and costly repairs.

Managing Fuel Quality Variability at Remote Ports

One of the biggest silent killers for Amazon River fleets is fuel quality variability. When you bunker fuel in remote river outposts, you rarely get the high-spec, filtered diesel found in major international ports. You are often dealing with fuel that contains high sulfur, condensation water, and fine particulates. This is where a high fuel tolerance becomes your most valuable asset.

If your engine uses a highly sensitive, high-pressure common rail system without adequate protection, dirty fuel conditions will lead to clogged injectors and unexpected shutdowns. For river logistics vessels, choosing generator sets with robust mechanical injection or enhanced filtration is a strategic necessity. You need a genset that can “digest” what the river provides without triggering a nuisance trip in the middle of a narrow channel.

Engineering for High Humidity Conditions and Tropical Heat

In the Amazon, the air is thick enough to feel. This constant moisture is a primary cause of electrical failure in ship diesel generator applications. When a genset sits idle during a loading stop, condensation forms inside the alternator windings. Without specific “tropicalization” treatments, this leads to short circuits and insulation breakdown.

Protecting the Alternator in a Confined Engine Room

The typical river barge generator set is often tucked away in a confined engine room where cooling and ventilation are limited. When you combine high ambient temperatures with stagnant, moist air, the thermal stress on your diesel generators increases exponentially. You must look for equipment that features anti-condensation heaters and high-grade insulation (Class H or better).

Effective cooling and ventilation design is not just about moving air; it is about ensuring the alternator can breathe despite the space constraints. A poorly ventilated confined engine room will shrink the lifespan of your voltage regulator and control electronics, leading to a higher total cost of ownership over the life of the vessel.

Dealing with Silt and Muddy Water: Cooling System Design

The Amazon is often called a “white water” river due to its immense sediment load. This silt acts like liquid sandpaper inside your cooling system. A standard ship diesel generator using raw water cooling will see its heat exchangers and sea water pumps erode rapidly. This is a primary factor in Amazon River logistics downtime.

Keel Cooling vs. Heat Exchanger for Cargo Barges

For many cargo barges and push-boats, keel cooling is the superior choice. By circulating the coolant through pipes attached to the outside of the hull, you create a closed-loop system that never “touches” the muddy river water. This eliminates the risk of silt clogging the engine blocks or destroying the internal heat exchanger. If your mission involves shallow water navigation or frequent stops in silty ports, this design choice significantly reduces your maintenance reality and long-term repair costs.

The Economics of Reliability: TCO vs. Operating Cost

In the world of commercial fleets, it is easy to get distracted by the initial purchase price. However, the real metric is the total cost of ownership. A cheap marine diesel generator might save you money today, but if its fuel tolerance is low and its electronics are too complex for remote repair, you are sitting on a ticking financial time bomb.

Comparing Operating Cost and Downtime Risk

Your operating cost—fuel, oil, and filters—is a predictable line item. The downtime risk, however, is catastrophic. In the Amazon, being stuck for three days waiting for a specialized technician with a diagnostic laptop can cost more than the entire genset itself. This is why electrical simplicity is a high-value feature for river logistics vessels.

When you choose generator sets with a proven track record of continuous operation, you are buying stability. You need a machine that can handle load fluctuations from cranes, pumps, and thrusters without falling into unstable frequency drifts. A robust weichai marine generator, for instance, offers the mechanical grit required to handle these cycles while keeping the total cost of ownership manageable.

Mission Matching: Choosing the Right Power for Your Fleet

Not every ship diesel generator fits every hull. A small ferry has different needs than heavy-duty cargo barges. To make an informed choice, you must analyze your specific duty cycle.

Prime Power vs. Continuous Duty at Sea

Most Amazon River fleets require a “Prime” or “Continuous” rating. Standby ratings are useless when your voyage lasts ten days without a break. Your generator sets must be rated for 100% load for unlimited hours. When evaluating a weichai marine generator, focus on the continuous operation specs. This ensures that the engine casting and cooling capacity are built for the long haul, not just for short bursts of emergency power.

The maintenance reality of your route is also vital. If your engineers have easy service access to common wear parts, your uptime stays high. Complex, shrouded engines that require proprietary tools are a liability in the jungle. Look for diesel generators that offer open access and standardized components.

Your Partner for Rugged River Power Solutions

Navigating the landscape of china diesel generator manufacturers requires a partner who knows the difference between a land-based spec and a true marine requirement. Shandong Uleen Generator Co., Ltd. (Uleengen) has been a specialized player in the ship diesel generator market since 2011. They don’t just assemble iron; they engineer generator systems for the most unforgiving environments on earth.

From their base in China, Uleengen exports high-performance diesel generators that are pre-configured for high humidity conditions and variable fuel quality variability. Whether you are looking for the rugged value of a weichai marine generator or a high-spec Cummins platform, Uleengen integrates the right control logic and filtration systems to ensure your river logistics vessels stay on schedule. Their commitment to ISO9001 and CE standards means you get a reliable ship diesel generator that meets global expectations but is built for the local challenges of the Amazon.

Conclusion: Powering the Future of River Transport

In the end, the success of your commercial fleets depends on the heartbeat of your vessel. In the Amazon, where dirty fuel conditions and extreme heat are the norm, you cannot afford to compromise on your power source. By prioritizing fuel tolerance, electrical simplicity, and robust cooling, you protect your investment and ensure your cargo barges arrive on time, every time.

Choosing a marine diesel generator for the Amazon is about more than just horsepower; it is about surviving the river. Stick with a reliable ship diesel generator manufacturer who understands the trade-offs of the tropics, and your fleet will thrive where others fail.

FAQ

Q1: Why is fuel quality variability such a problem for Amazon river vessels?

A: Remote ports often have fuel that sits in tanks for long periods, leading to water condensation and microbial growth. High fuel tolerance and multi-stage filtration are the only ways to prevent dirty fuel conditions from damaging your generator sets.

Q2: Can a standard land-based genset be used for river barge logistics?

A: No. Land-based diesel generators lack the anti-corrosive coatings, marine-grade heat exchangers, and the specialized insulation required for high humidity conditions. Using them on a boat leads to rapid failure and safety risks.

Q3: How do I reduce the downtime risk in remote rainforest areas?

A: Prioritize electrical simplicity and mechanical robustness. Avoid over-complicated electronic systems that require specialized factory technicians. A Weichai marine generator is often preferred here because it is easier to service with basic tools.

Q4: What is the best cooling method for silty “white water” rivers?

A: Keel cooling is often the best choice for river logistics vessels in silty water. It keeps the muddy water away from the engine’s internal components, significantly reducing wear and the frequency of cleaning heat exchangers.

Q5: Does Uleengen provide technical specs for different Amazon river boat types?

A: Yes. You can find a detailed cost-benefit analysis of Weichai vs. Cummins marine generators (available soon) or view specific Weichai Series marine generator specifications through Uleengen to match your boat’s specific duty cycle.