Hidden Downtime Costs of Diesel Generator Marine Power When Failure Happens at Sea

Introduction: Downtime at Sea Is Not a Line Item

If you buy a diesel generator marine system the same way you buy land-based generator, the numbers look clean. Price, marine diesel fuel consumption, service intervals, done. Then a real outage happens at sea, and the spreadsheet stops helping. The hidden costs of power show up fast, because downtime at sea is not “lost convenience”. It is lost control.

This article stays away from repair tips and brand talk. It focuses on what decision makers care about most: what really drives downtime cost in a marine diesel generator system, why those costs get ignored early, and how to frame choices so a genset supports operations instead of becoming a risk you keep managing.

Why Marine Downtime Costs Are Structurally Underestimated

On paper, downtime looks like a maintenance event. In practice, downtime is an operational event. That difference is the whole problem.

Downtime at Sea Is Operational, Not Optional

Onshore, an outage often becomes a scheduling headache. You call a technician, shift loads, wait. On a vessel, power supports navigation, comms, pumps, cooling, and safety systems. Even when propulsion is not electric, the ship still runs on stable power. When the genset trips, the next decision is rarely “fix it later”. It is “what can keep running right now”.

That is why downtime cost at sea grows faster than most project teams expect. It is not just the hour count. It is the forced choices that hour creates.

Why Budget Models Miss Marine Reality

Many budgets are built around operating cost. Fuel, oil, filters, planned service. Those are real. But marine projects also pay for things that never appear as a line item.

A short outage can mean a missed tide window, a berth delay, a route change, extra port time, or a crew kept on standby while the schedule slides. None of that feels like “generator cost” during procurement. It feels like “operations” later. That separation is exactly how hidden costs of power survive the approval process.

Operating Cost vs Downtime Cost in Diesel Generator Marine Systems

Here is a blunt way to think about it. Operating cost is the cost you expect. Downtime cost is the cost you cannot postpone.

The Cost You Can Measure vs the Cost You Cannot Delay

Operating cost of the genset is easy to measure. You can forecast marine diesel fuel consumption based on duty cycle. You can price consumables. You can plan service windows.

Downtime cost is different. It is the value of time, the value of stability, and the value of not forcing risky decisions. When power becomes unstable, the vessel does not “pause”. It degrades. Loads get dropped. Cooling gets tight. Alarms pile up. A small electrical event becomes a system event.

If you have ever walked into an engine room after a trip, you know the mood. It is hot, loud, and a little tense. That tension is part of downtime cost too. It shows up as conservative operating choices that reduce efficiency for days.

Why the Cheapest Option Becomes the Most Expensive

Low purchase price of the marine diesel generator set can look smart when you only compare operating cost. But marine conditions punish weak assumptions.

A diesel generator marine package that is slightly mismatched to the load profile may still run. It just runs closer to the edge. That edge is where nuisance trips, temperature issues, and unstable voltage start. The result is not one big failure. It is a pattern of smaller interruptions that slowly rewrite your schedule.

In other words, you do not “pay” for the wrong choice once. You pay for it in fragments.

Common Downtime Triggers in Marine Diesel Generator Applications

Downtime rarely starts with one dramatic defect. It usually starts with stress that was predictable, but not treated as a design input.

Continuous Load Stress Under Real Sea Conditions

Many marine generator sets operate in prime power mode, not standby power mode. That matters. Continuous load changes everything: heat balance, wear patterns, and the system’s tolerance for small problems.

Land projects often assume generous cool air, easy access, and flexible load shedding. A vessel has less room, higher ambient heat, and fewer “nice to have” systems. Even a basic cargo ship engine room can feel like a closed box when the vessel is in warm waters and the genset is running hard for hours.

If the load profile includes long steady demand plus frequent step changes, the genset needs enough reserve to absorb those changes without falling into unstable operation.

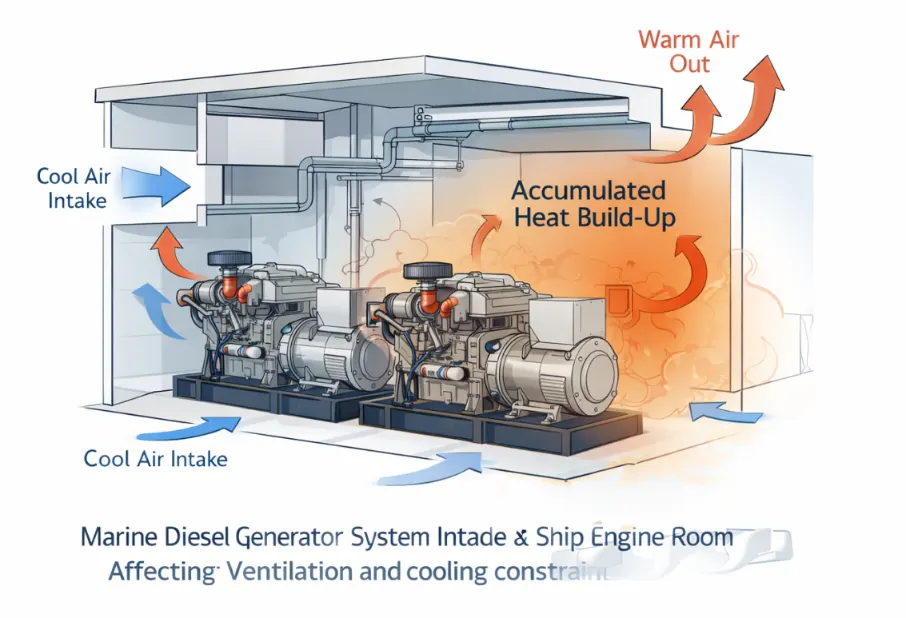

Cooling, Ventilation, and Space Limits

Marine installations compress a lot of equipment into tight spaces. Cooling and ventilation limits do not just reduce efficiency. They shrink the margin for error.

When heat cannot leave the space fast enough, everything runs hotter than expected. That includes controls, wiring, and alternator components. The system becomes sensitive. A minor restriction in airflow, a slightly dirty heat exchanger, or a fan that is not performing at spec can turn into an engine breakdown event. Not because the engine is weak, but because the Marine diesel generator system cannot breathe.

This is one reason “nameplate power” is not a safe anchor for Marine diesel generator decisions. Real power is what the system can carry without drifting into thermal stress.

Fuel Quality Variability and Storage Reality

Fuel availability is not the same as fuel usability. Marine fuel quality varies by port, by supplier, and by storage conditions on board. Contamination, water, and instability during long storage can all increase risk.

This is where downtime cost creeps in. Fuel issues do not always stop the genset right away. They often cause rough starts, unstable combustion, or slow performance drift that triggers alarms later, at the worst time.

If your vessel depends on onboard power for long stretches, fuel logistics becomes part of reliability, not a procurement afterthought.

Why Marine Downtime Cannot Be “Fixed Later”

Marine operations punish delayed decisions. When something goes wrong, the clock does not stop, and the ocean does not care.

No Workshop, No Easy Swap

Onshore, a problematic generator set can be swapped, serviced, or replaced with less operational pressure. At sea, spare capacity is limited. Access is limited. The maintenance window is real, but small. And the cost of “waiting until port” can be far higher than the cost of the part.

So the real question becomes: how often does the system force you into that corner?

Downtime Cascades Faster Than Onshore Failures

Marine power systems are tightly coupled. When one section becomes unstable, other sections are affected quickly. Load priority becomes an emergency tool, not a planning tool.

This is why internal engine failure is only part of the story. The bigger risk is cascading instability across electrical loads that were never meant to see brownouts or frequent transfers. The impact spreads, and it spreads fast.

How Diesel Generator Marine Decisions Should Be Framed Instead

If the goal is fewer operational surprises, the decision frame has to change. Not a little. A lot.

Start With Failure Tolerance, Not Purchase Price

A useful procurement question is not “what is the cost per kW”. It is “what kind of downtime can this vessel tolerate”.

If the answer is “almost none”, then the system needs reserve, clean load management, and realistic thermal design. If the answer is “some downtime is acceptable”, the system may still need reserve, just less. Either way, failure tolerance drives design logic. Price follows.

Think in Systems, Not Single Machines

Marine diesel generator is a component. The system is the asset.

System-level reliability comes from how the genset interacts with loads, cooling, ventilation, controls, and fuel supply. It also comes from how prime power duty differs from standby power duty, and how the genset is expected to respond during step loads and long runs.

That is why good Uleengen teams spend more time on load priority and operating scenarios than on glossy brochures.

Conclusion: The Real Cost of Power at Sea Is Lost Control

Hidden costs of power in marine projects do not hide because they are rare. They hide because they live outside the generator budget. They show up as delays, constrained choices, risk exposure, and operational stress.

When a diesel generator marine system is selected and integrated around real duty cycle and real installation limits, downtime becomes less frequent and less severe. When it is selected like land-based equipment, downtime becomes a repeating tax.

The goal is simple: keep control. Stable power keeps schedules stable. It keeps crews calm. It keeps small issues from turning into big ones. That is the only “cost saving” that matters at sea.

Uleengen: A Practical Partner for Marine Generator Sets

Shandong Uleen Generator Co., Ltd. (Uleengen) builds intelligent generator sets for customers who care about uptime, not slogans. Since 2011, Uleengen has focused on diesel generators and generator sets across a wide power range, and supports multiple engine platforms, including Yuchai, Cummins, Perkins, Deutz, Weichai, and more. Product coverage includes marine generator options, gas generator options, and control solutions such as auto-start panels, synchronization panels, and ATS configurations, with common controller choices like Deepsea, Smartgen, ComAp, and Deif. Uleengen also highlights manufacturing standards and quality systems, including ISO management certifications and widely used generator standards, plus international market certifications used in export projects. If your marine project needs a genset that matches real duty cycles, real installation limits, and real service expectations, Uleengen is positioned as a power partner that speaks in engineering terms and delivers in project terms.

FAQ

Q1: Why does downtime at sea feel so much more expensive than downtime on land?

A: Because downtime at sea forces operational choices right away. You are not just losing power, you are losing options, and that can turn into schedule loss fast.

Q2: Does marine diesel fuel consumption matter if downtime is the main cost?

A: It matters, but it is rarely the biggest surprise. Fuel is predictable. Downtime cost is not, and it tends to hit when the vessel has the least flexibility.

Q3: What is the most common “quiet” cause of marine generator downtime?

A: Heat and airflow limits. Cooling and ventilation limits shrink your margin, and small stress builds until the genset starts tripping or drifting.

Q4: Prime power vs standby power sounds like paperwork. Why should you care?

A: Because it changes what the system is built to do. A genset that lives in prime power duty needs different reserve and different expectations than standby power duty.

Q5: If you have redundancy, does that solve the downtime problem?

A: It helps, but it is not a magic shield. Redundancy works when load priority, transfer behavior, and thermal design are handled well. Otherwise, you can still get cascading instability.